TJ. 003

End of Year 2025 - How has business scope has been refined?

How has Vale Industrial Design’s focus narrowed over the past year? I take a look at how things have progressed, from leaving my steady career in 2024, to giving myself the thrill (and mild panick attacks) of starting a business from scratch. Crucially, I always aimed to make this as lean a process as possible - no huge upfront investments with the goal of making this a self supporting venture as soon as possible.

In November 2024, I ended my employment as a Mechanical Design Engineer from an industrial equipment manufacturer in Oxford, UK. I knew I needed a change, but I didn’t know what I planned on doing next. I decided to simply leave, and let thoughts creep in over the next few months. This never worried me as I’m always busying myself with something.

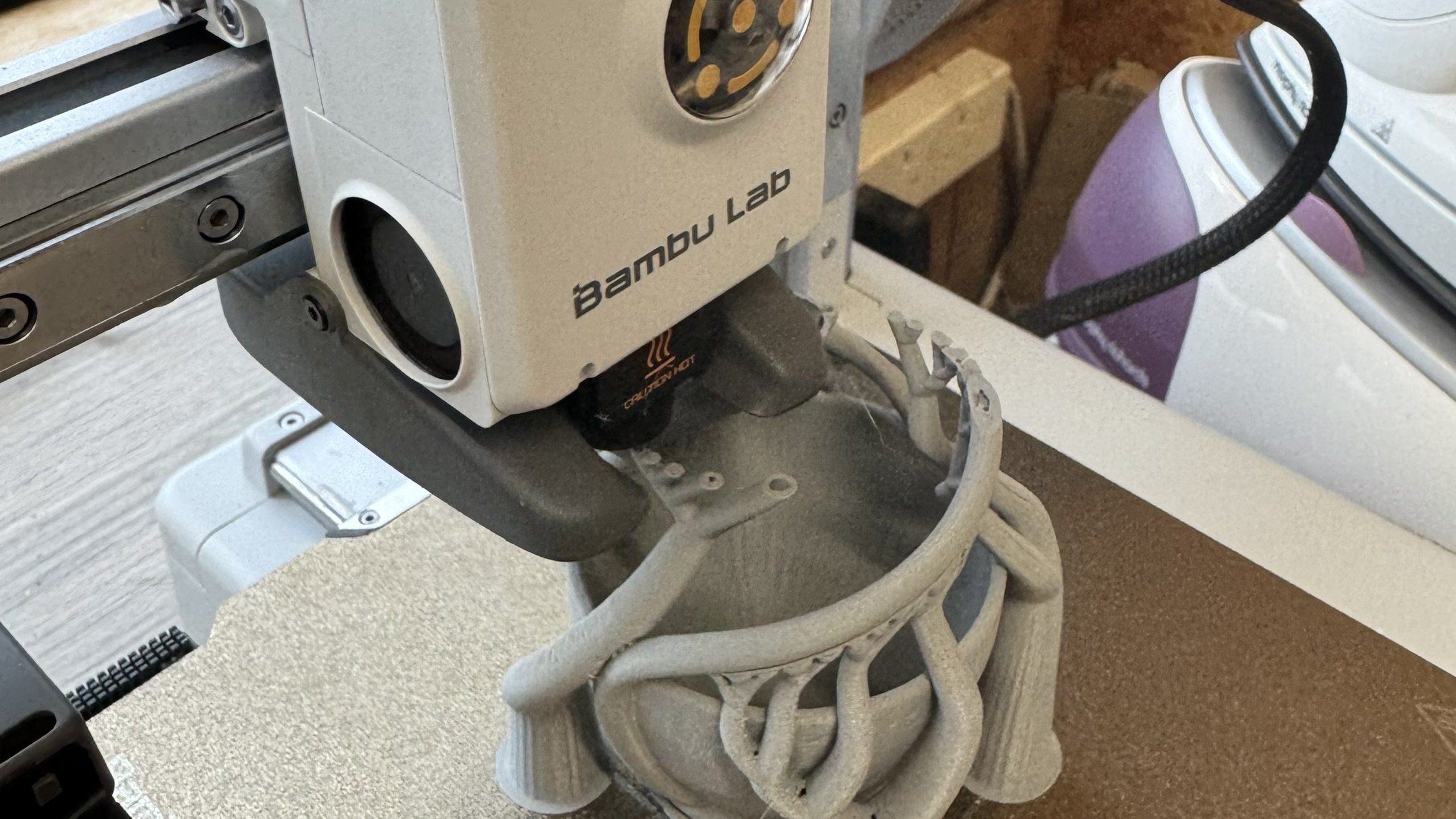

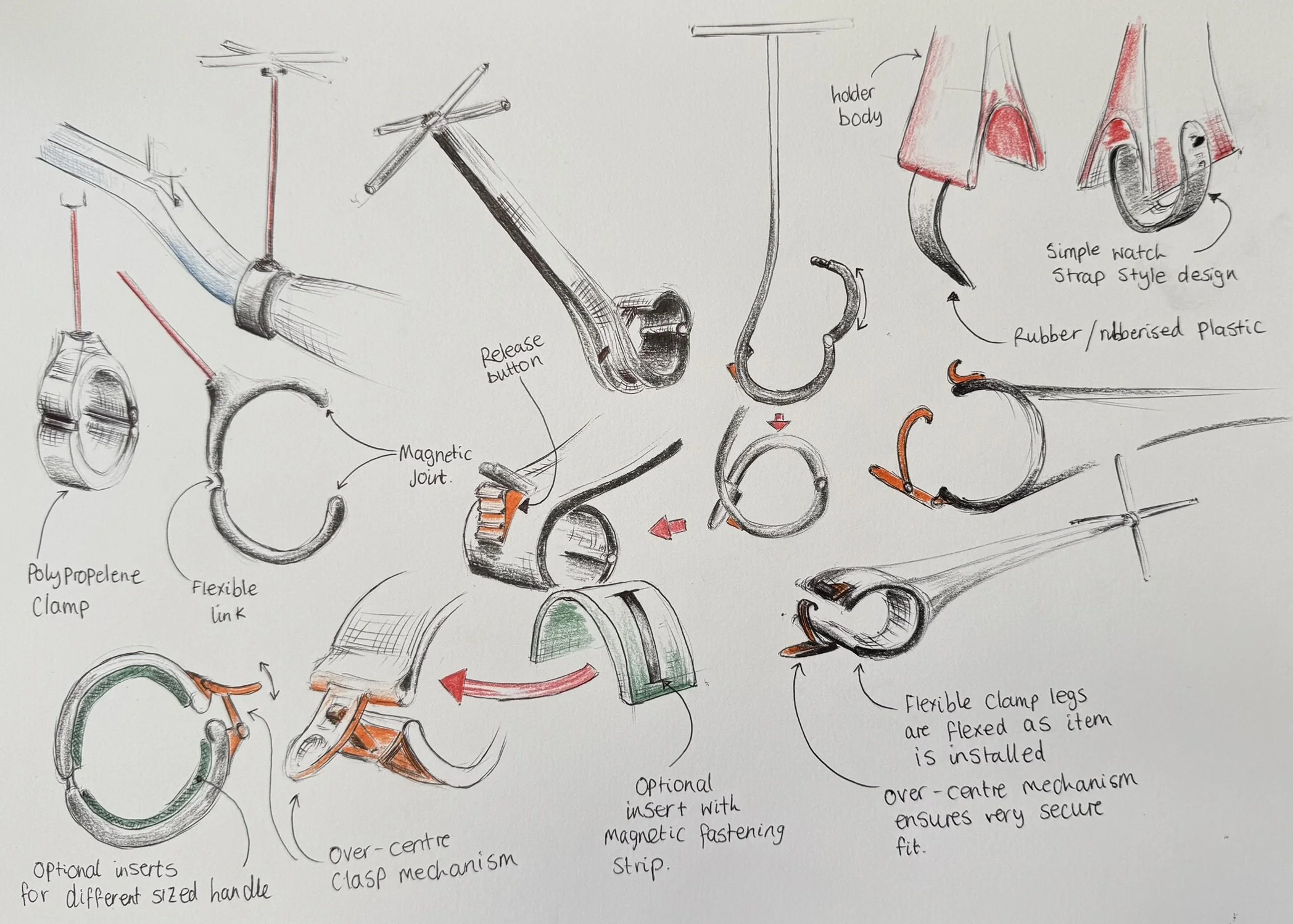

I bought a cheap 3D printer to play around with. I hadn’t been so exposed to the additive scene throughout my career, and I was surpised at the low cost of an entry level product. I had some fun for a few months making random widgets and wasting lots of PLA - it was fun. I also found my love for hand-sketching again, and it ignited something when I started applying it to technical creativity.

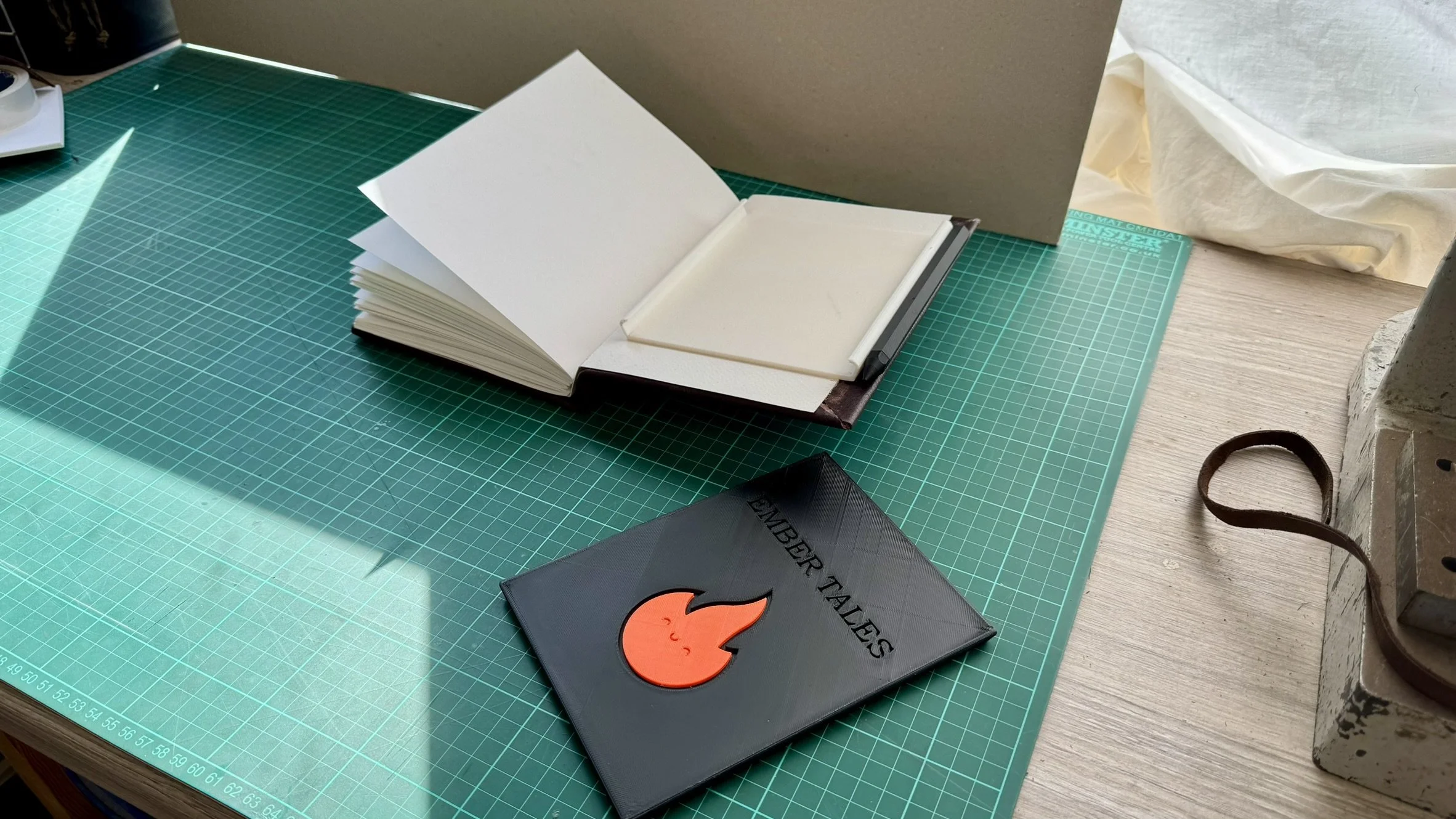

I created an account of Fiverr - a freelance platform, priced myself ridiculously low and got my first small job through in March 2025. I designed and built a leatherbound book with an integrated tablet mockup. Not a product I was interested in, but it didn’t matter - it taught me about pricing, customer communications as well as lead times and delivery. A small job that I made a huge loss on - lucky customer 😊

Between March 2025 and July 2025, I received a few various jobs through the platform which forced me to learn how to adapt to different customer preferences, hold myself steady on pricing negotiations, and make sure I didn’t over-promise. I also ensured my technical know-how stayed up to date whilst keeping on track with the skills i wanted to develop for myself. I streamlined the development process and pushed to be a low cost designer and prototype engineer, making use of my technical background aswell as solid understanding on DFM, DFA and assembly/build/manufacturing. I quickly realised that the Fiverr platform did not offer adequate flexibility for a service like myself, so I moved to Upwork.

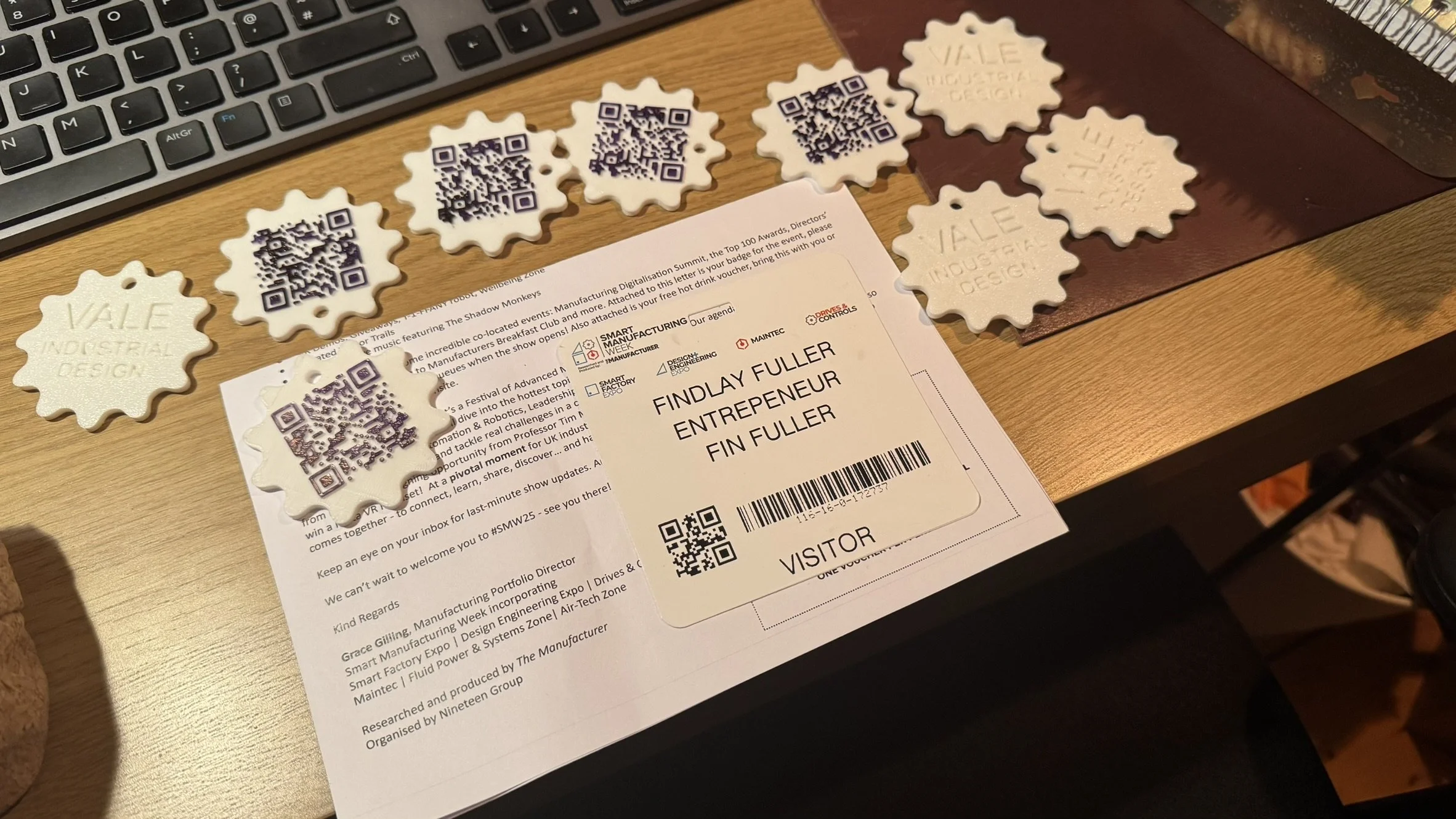

Hardware Pioneers London and Engineering/Smart Manufacturing week NEC got me talking to individuals and businesses within the hardware development and testing fields. I didn’t want to self-promote but knew it was essential (I also desparately needed to get better at it) I made a few handouts with the challenge of getting rid of all of them at the event. I didn’t want to pay to exhibit, and thought I could communicate my services across effectively as a visitor instead.

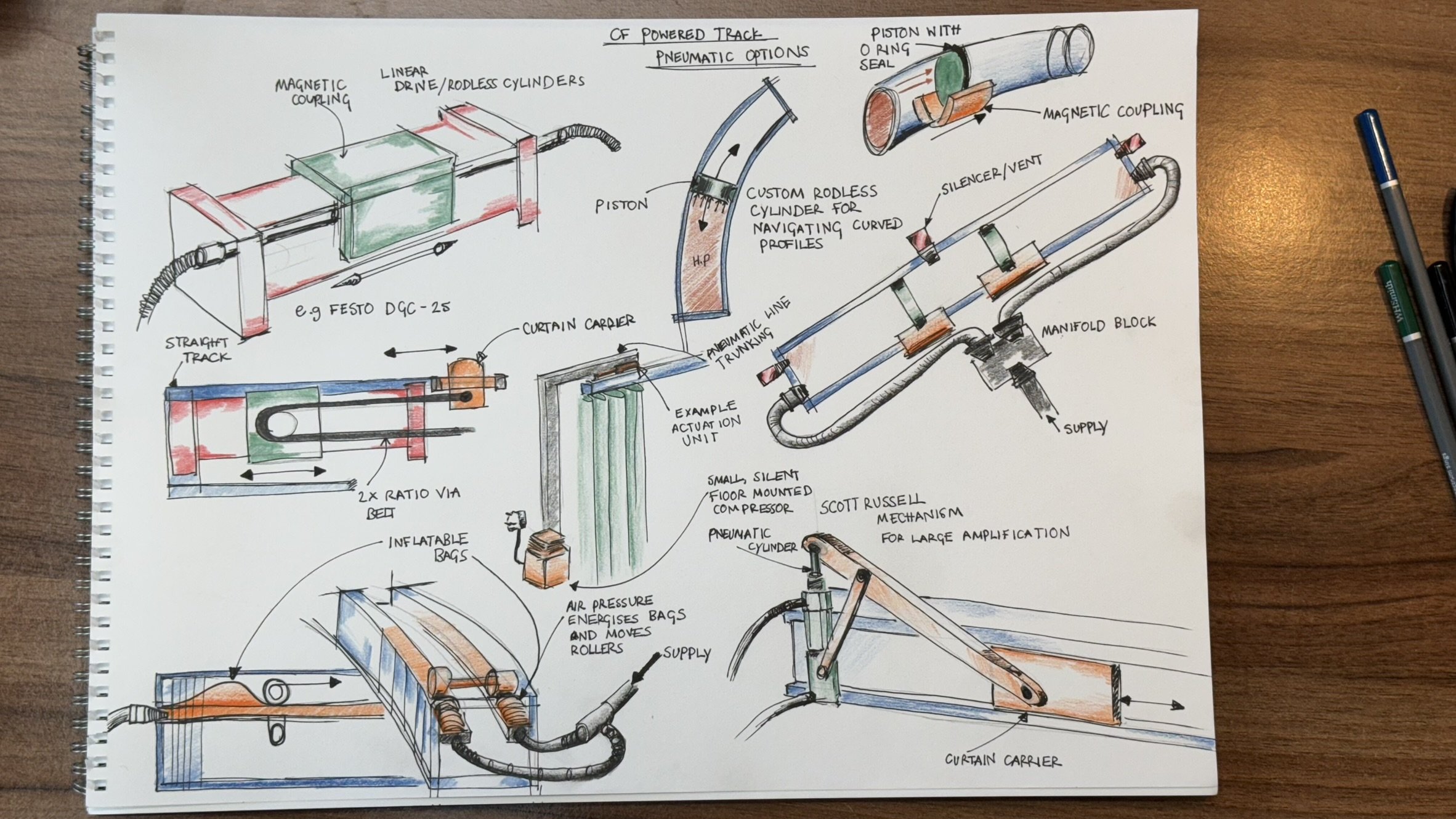

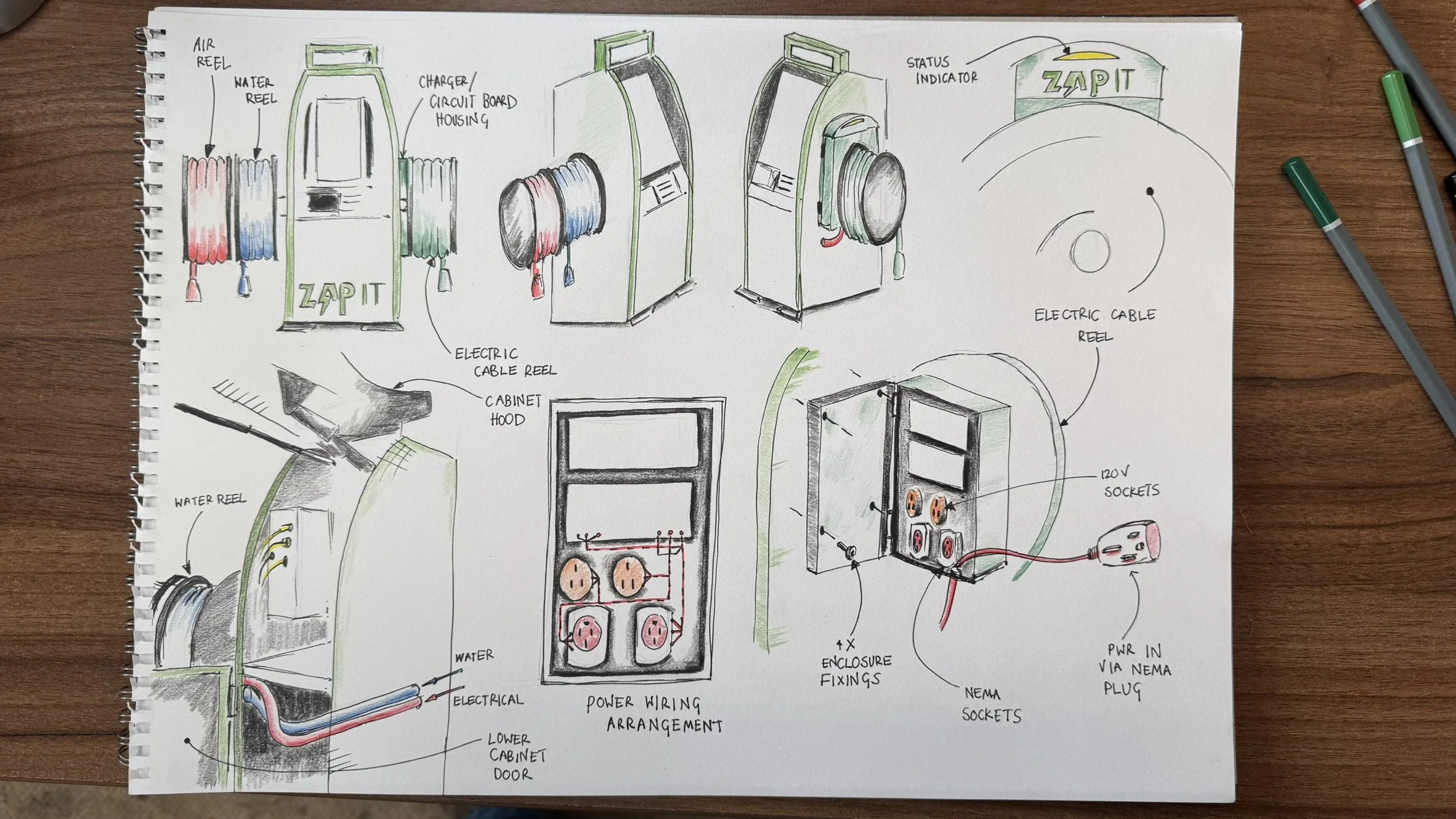

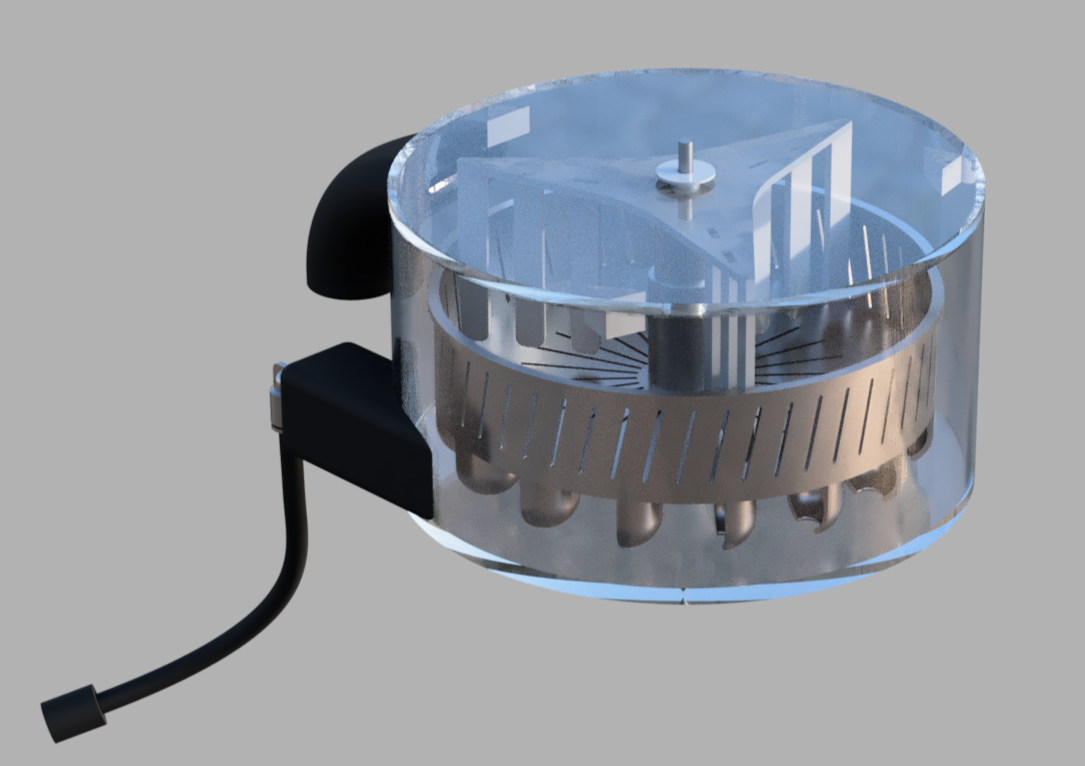

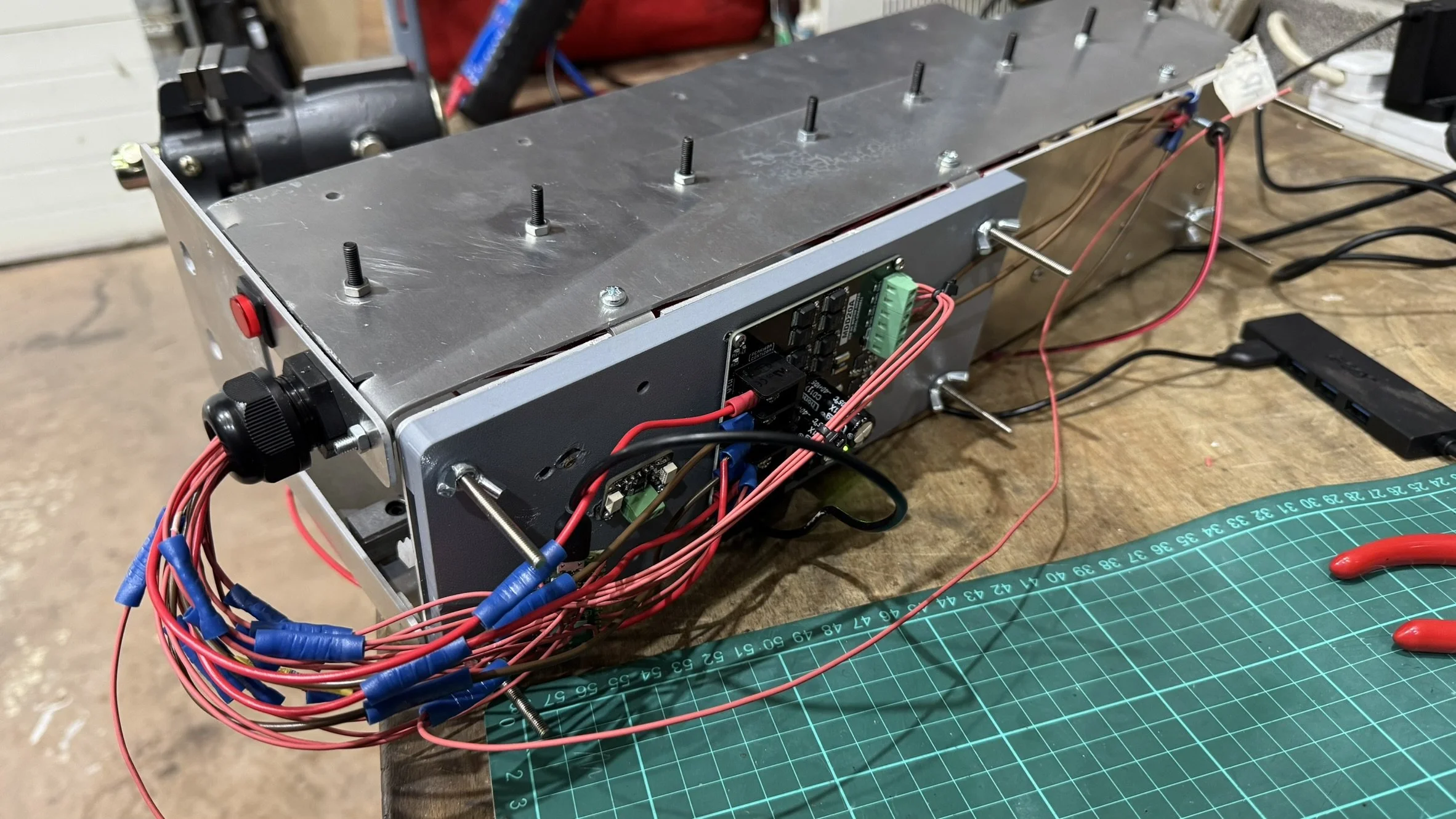

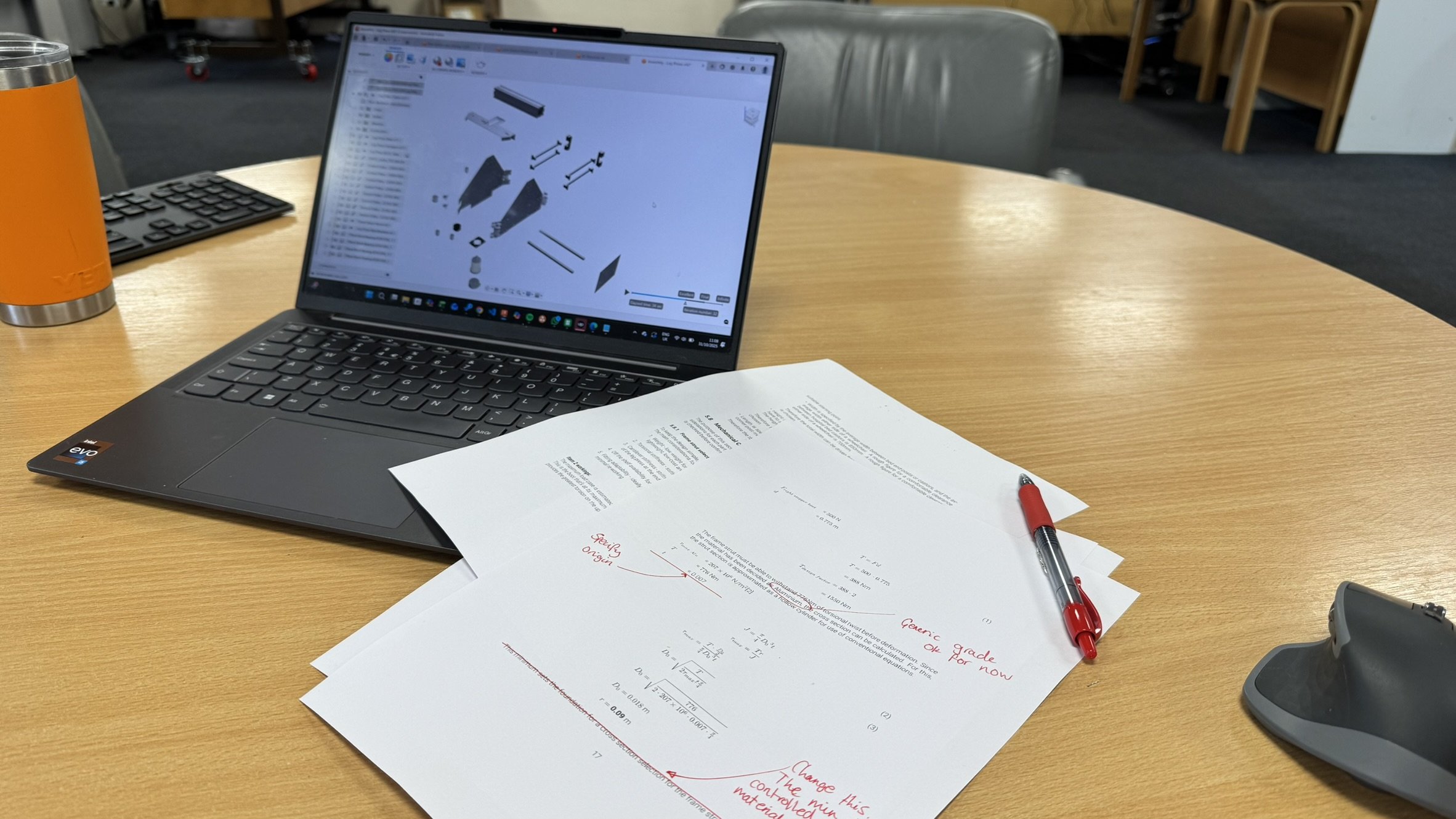

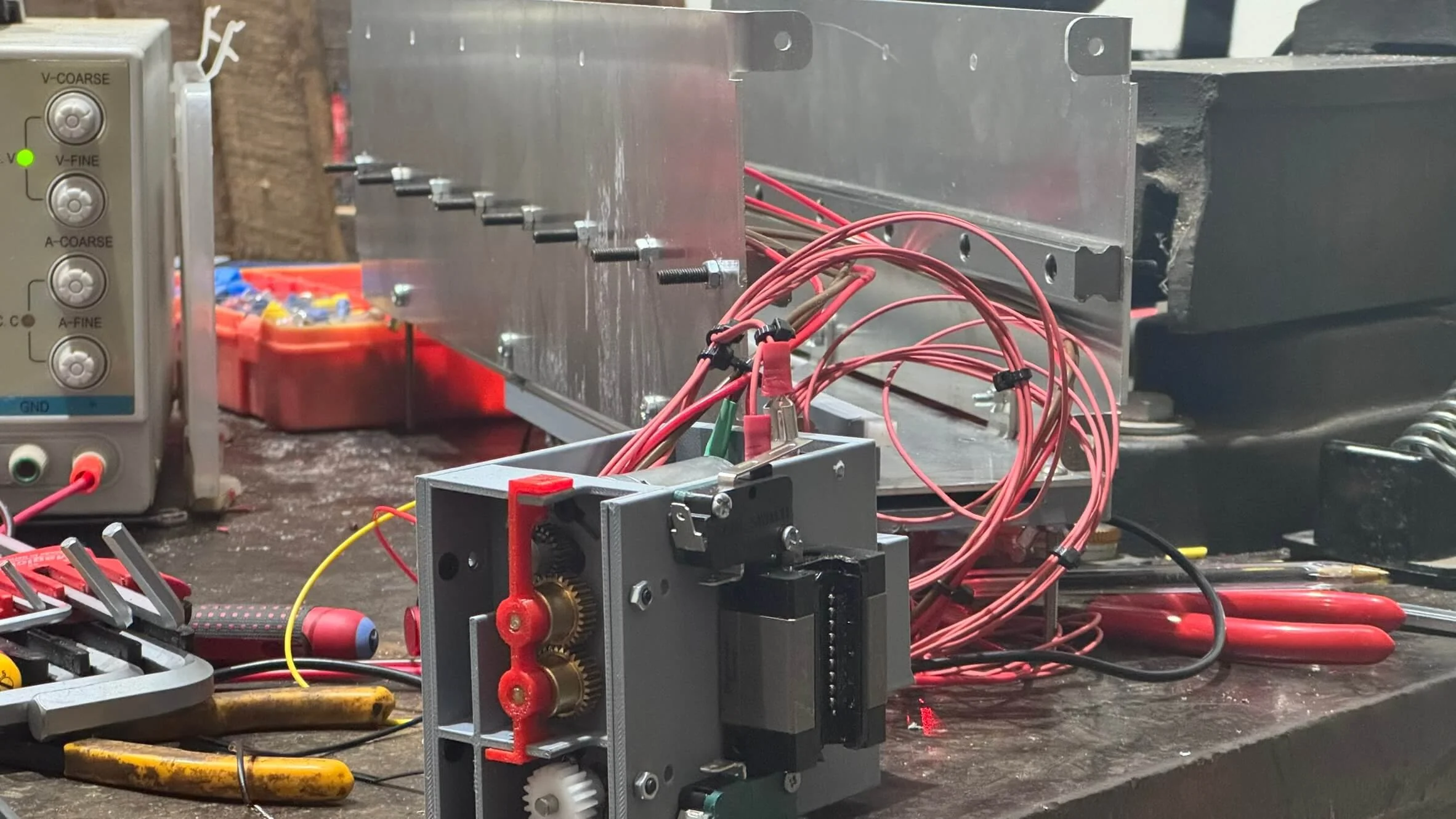

In July 2025, I received my first very exciting project through Upwork - the development of a new piece of electromechanical equipment. A product area that I was particularly interested in. This was hugely challenging to conceptualise and I worked closely with the customer to understand requirements in real detail before we began. I poured hours and hours into this work, not only on the project, but on how I structured the design phases throughout the project. I also finally got to bring in my professional skills as a mechanical engineer into the mix through technical calculations and validations. Factors such as DC motor sizing, movements and kinematics were a big part of this work. The product build was a great opportunity for me to develop my programming and controls knowledge - something I’d worked on previously and began accelerating the year before.

In August 2025, another piece of work joined. This happened to be within the same product realm, and again it was a massive boost - I could really use my career knowledge now, and started building on ways to professionally present information to customers who weren’t so technically minded. I counted myself lucky that I now had two projects within the same field, but I think it was largely due to the extensive personal marketing I’d been doing on freelance platforms - Finally I was honing in on something more specialist!

November 2025 - Things quietened up quite quickly - customers put projects on hold, and I learnt about the instability of freelance work for real. This is the nature of it. I guess the moral of this year’s story is to - simply start. In March, I send a book to Kuwait, and in October I worked closely with private individuals to develop their own autonomous solutions - aligning much more closely with the type of engineering I expected to be involved in.

December 2025 - Vale Industrial Design went private Ltd which was very exciting. The aim is to bring officiality and industry recognition to my organisation. Some exciting plans and projects are lined up for 2026 and I’m very excited to keep it growing!

Merry Christmas and a Happy new year everyone🎄

Fin

TJ. 002

09/12/2025

Mistakes are always made - it’s part of any new engineering operation. How do we ensure the impacts are minimal, and that the result of these can be insightful and beneficial for a business?

Continuous Improvement and Lessons Learnt are widely regarded as being a ‘good’ practices within engineering and manufacturing, however it’s at this point where it often fades away into the background as more pressing jobs come into focus, and urgency filters out these ‘nice to haves’.

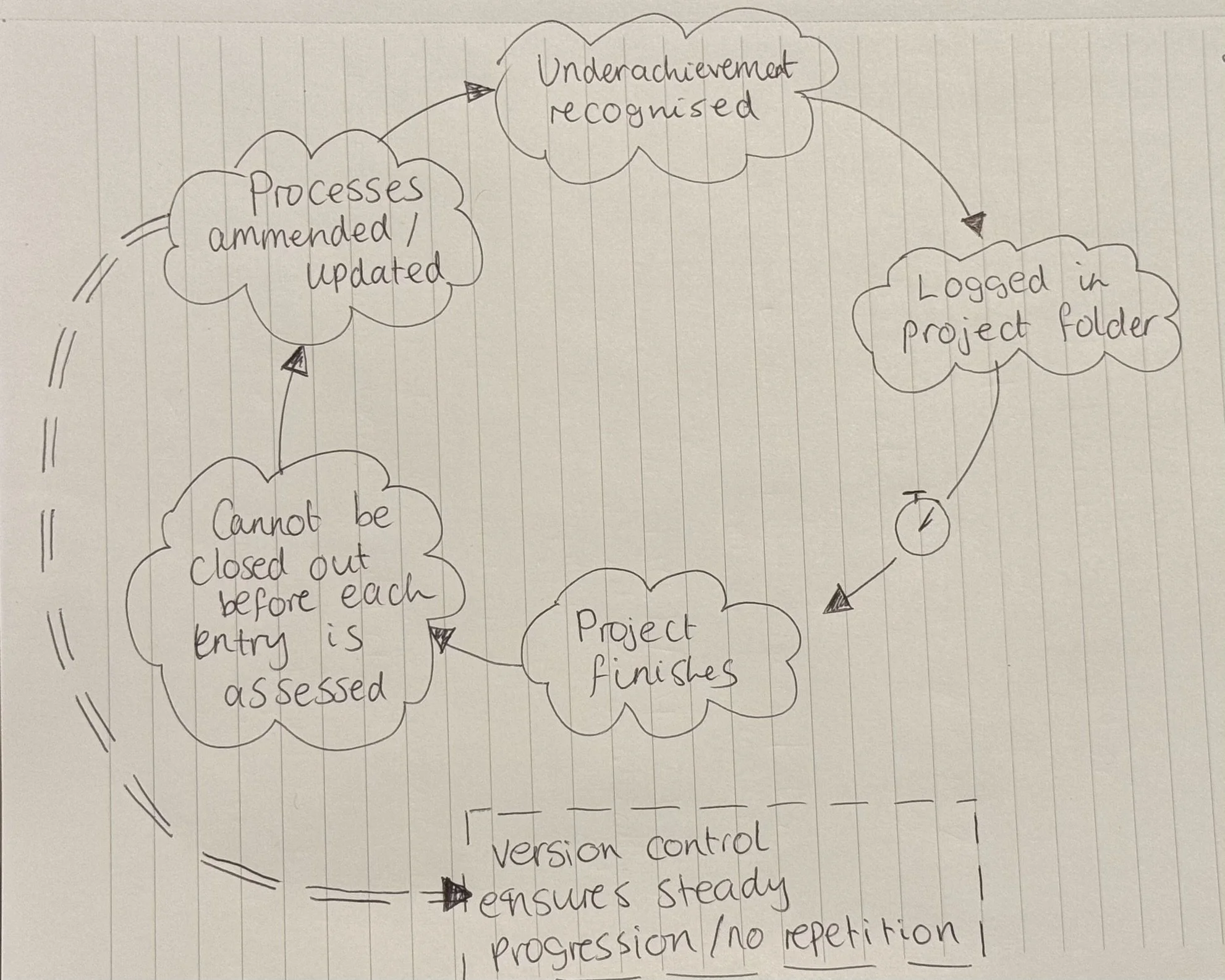

At Vale Industrial Design, lessons learnt are considered hugely important for future proofing the business. A continuous improvement strategy aimed at lessons learnt is one of the key reasons why underperforming results are always recorded, and at a bare minimum, analysed for their ability to ammend current processes. It’s a simple solution, and requires nothing more than a trained conscience which reacts positively to failure, always seeing it as a gold mine for data and future improvements.

So far, working off a premise where any project cannot be closed/officially completed is proving effective. It forces engineering and design defects to be looked at in detail, and applied to any relevant templates and blueprints before they’re crossed off - line by line. This does a few things:

It ensures documentation is being reviewed regularly and not becoming forgotten.

It extracts every last detail and valuable data piece from every project

Process Representation

Although minimal, this small process is already proving itself to deliver hugely valuable insight that’s based off real world testing.

A less technical post, but I hope you found it interesting. Designing and building technical feats of engineering has always been tied to procedural efficiency - How can you get from position A to position B with as little drag, and as few turn-arounds as possible. More importantly - how can you ensure that subsequent execution of tasks will be superior to the last?

TJ. 001

A first post on the technical journal where I explore the discussion around upfront engineering design work before the first build is carried out. A quick showcase of an ongoing project is also included with a brief description of how it runs.

25/11/2025 - FIRST POST!

Up For Debate - How much front-loading and upfront engineering design is optimal for a truly new piece of equipment, before the first build begins?

I've pondered this question extensively whilst working on a completely new piece of automated equipment for niche business sector (undisclosed!). A modern approach, whether you're using V-model, Agile or iterative type processes follow a similar principle of design, test, inform, repeat but the first step can be the hardest to get right, because - there's no feedback on the first instance.

This particular build has heavily informed subsequent design modifications and changes. Lessons learnt have been logged, and process structure tweaked for next time!

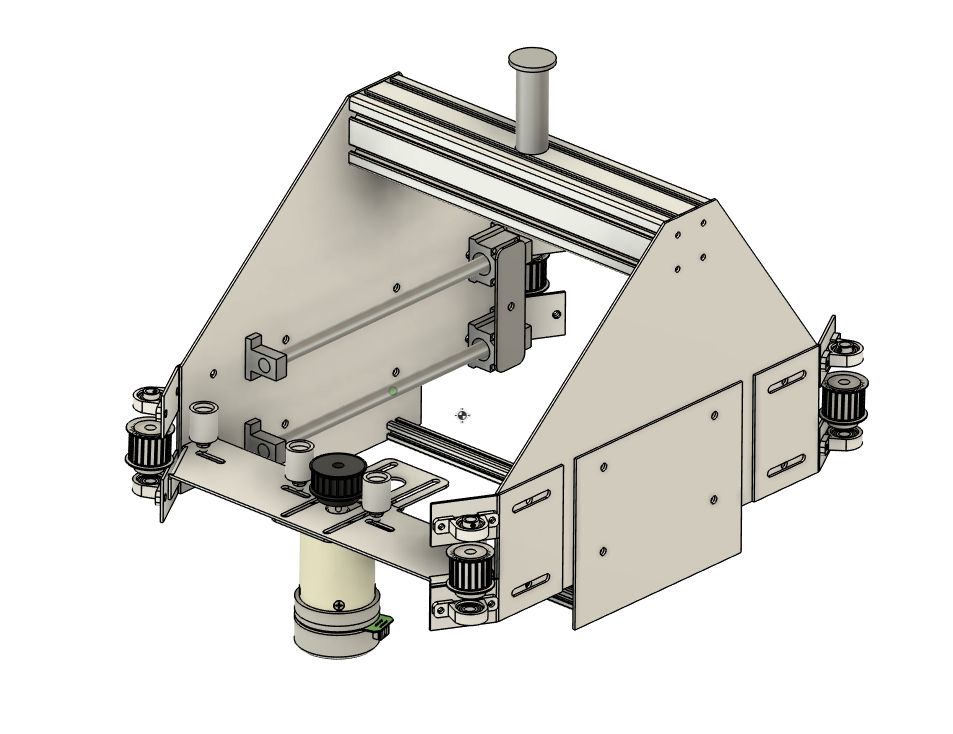

Here we have the disassembled 2-axis motion platform, DC powered and controlled with a Raspberry Pi Pico running Micropython for a quick and efficient prototype.