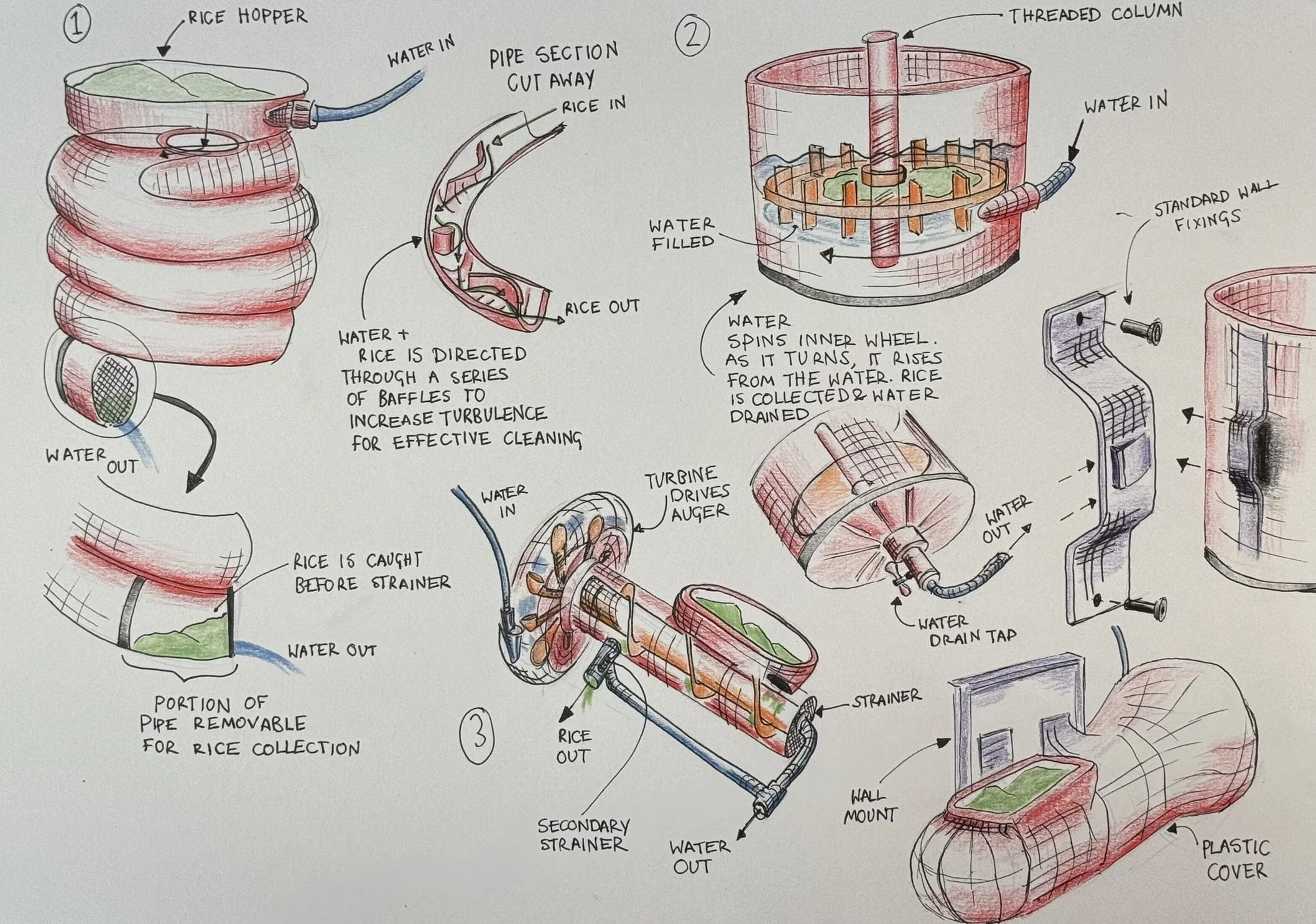

Hand - Drawn Concept Sketches

Kickstart your product development with this initial design service. The process of sketching out ideas and solutions is proven to increase divergent thinking, and drive new thoughts. Drawing and sketching allows us to develop your product and solution ideas from a solid foundation, ensuring important details are incorporated into the first prototype.

Generate “Blue-Sky Thinking”

Explore new design avenues

Critique particular details

Uniquely crafted drawings for your project records