TJ. 002

09/12/2025

Mistakes are always made - it’s part of any new engineering operation. How do we ensure the impacts are minimal, and that the result of these can be insightful and beneficial for a business?

Continuous Improvement and Lessons Learnt are widely regarded as being a ‘good’ practices within engineering and manufacturing, however it’s at this point where it often fades away into the background as more pressing jobs come into focus, and urgency filters out these ‘nice to haves’.

At Vale Industrial Design, lessons learnt are considered hugely important for future proofing the business. A continuous improvement strategy aimed at lessons learnt is one of the key reasons why underperforming results are always recorded, and at a bare minimum, analysed for their ability to ammend current processes. It’s a simple solution, and requires nothing more than a trained conscience which reacts positively to failure, always seeing it as a gold mine for data and future improvements.

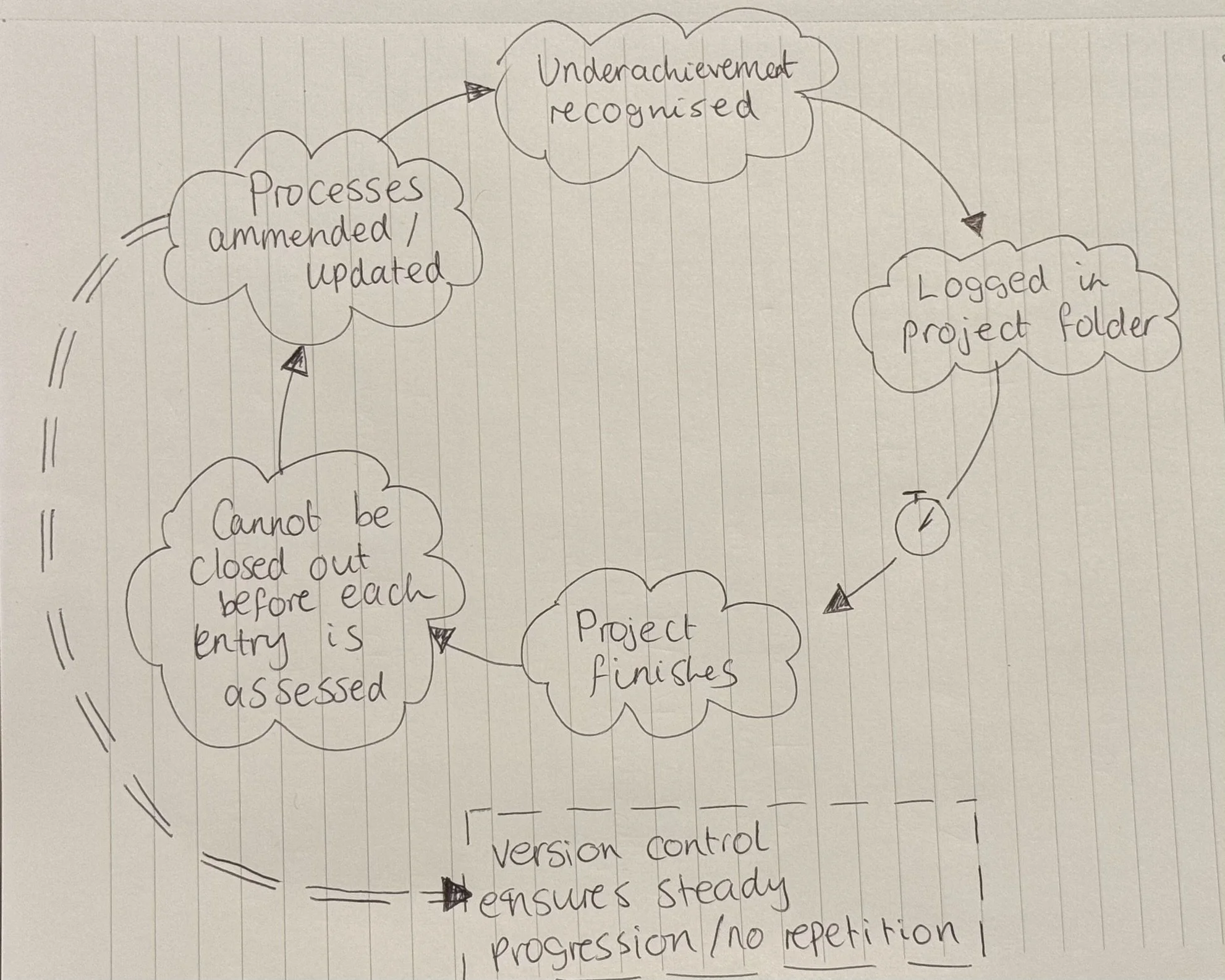

So far, working off a premise where any project cannot be closed/officially completed is proving effective. It forces engineering and design defects to be looked at in detail, and applied to any relevant templates and blueprints before they’re crossed off - line by line. This does a few things:

It ensures documentation is being reviewed regularly and not becoming forgotten.

It extracts every last detail and valuable data piece from every project

Process Representation

Although minimal, this small process is already proving itself to deliver hugely valuable insight that’s based off real world testing.

A less technical post, but I hope you found it interesting. Designing and building technical feats of engineering has always been tied to procedural efficiency - How can you get from position A to position B with as little drag, and as few turn-arounds as possible. More importantly - how can you ensure that subsequent execution of tasks will be superior to the last?