Rice Starch Removal Device

The customer was looking for a product solution to automate the process of hand-washing uncooked rice grains in the consumer homeware sector. This was a novel product with some crucial requirements, making it suitable for the home environment.

Customer Brief and Specification

100% powered through domestic water supply

No electrical components

Maximum 5kg rice through the system at once

Prototype made with off the shelf parts, and 3D printed parts

Must be wall mounted using traditional fixings

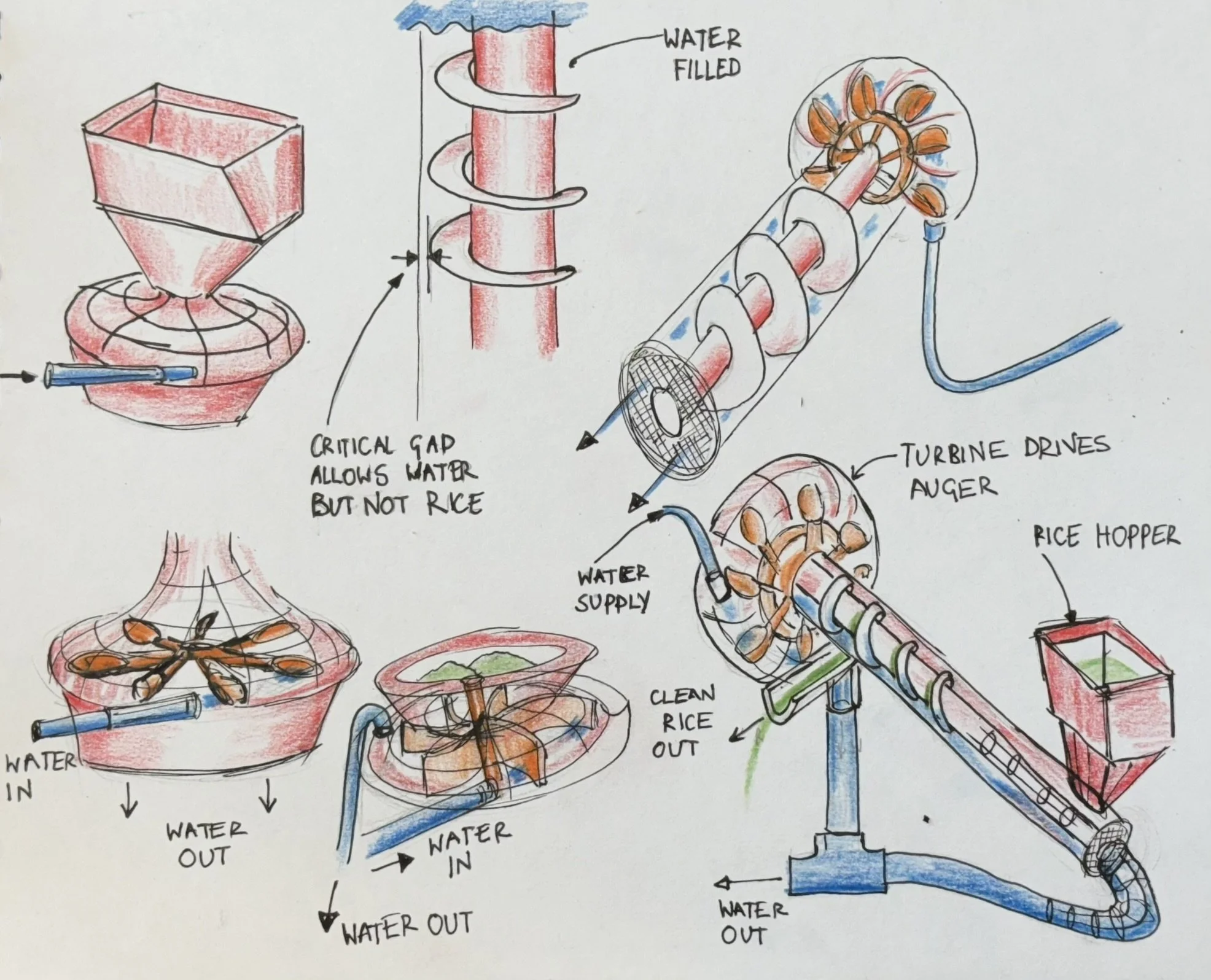

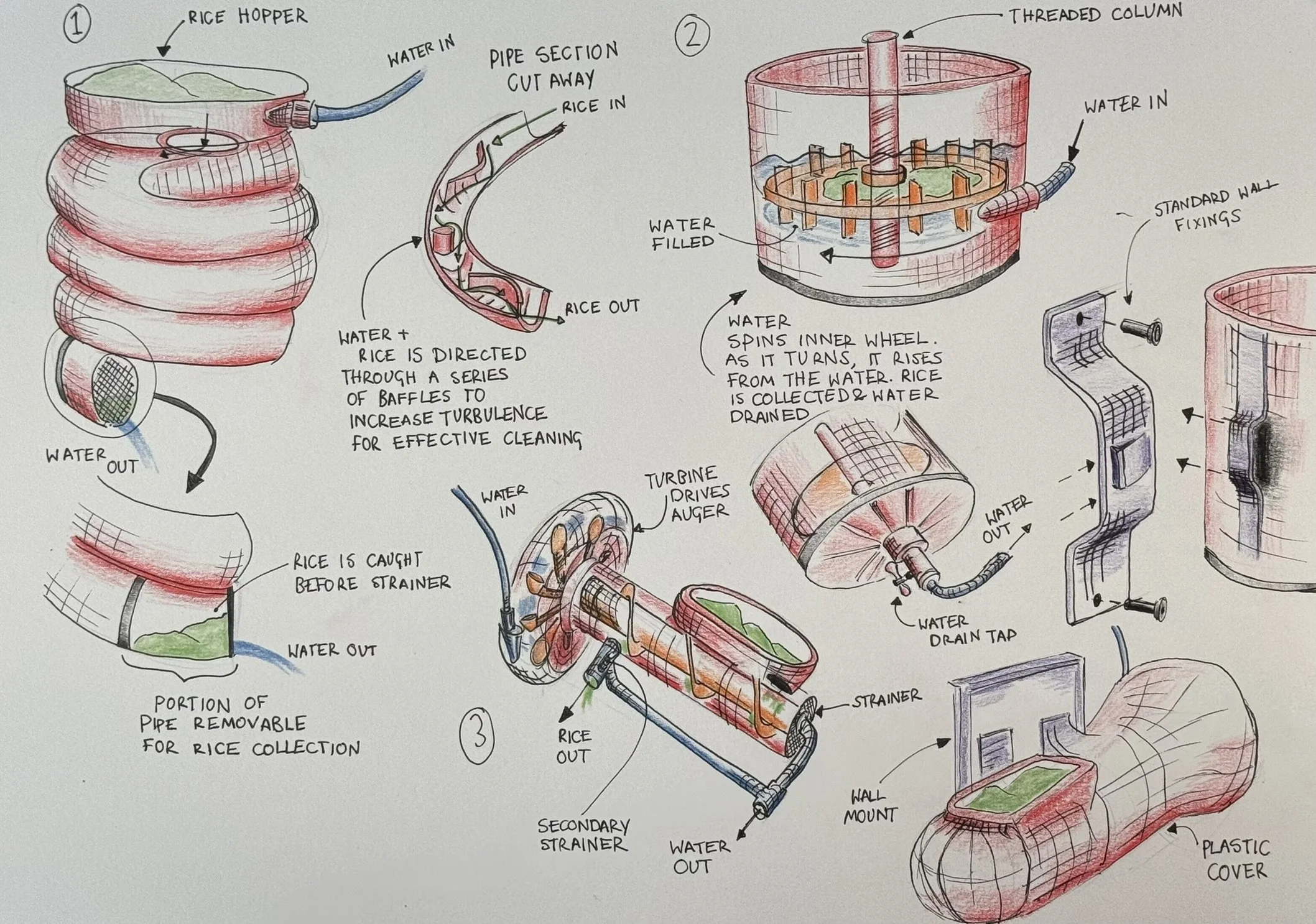

Concept Visualization

Abstract ideas were explored through this concept drawing phase. The key requirements kept in mind the whole time. Considerations and design challenges that came about during this stage were:

Using water from a single supply as both the power fluid and washing agent

A way of removing the cleaned rice from the container post washing

Separating the rice and water. Removing the possibility of the grain being swept into the outlet

Concept Selection and 3D Modelling

Inspired by the simplicity of household salad spinners, design 2 was chosen to develop further.

Basic model drafted

Adaptations made from the original concept, such as:

Moving the water outlet to the top of the container, allowing a tabletop based unit

Discarding the idea of a threaded axle due to overcomplication

Model optimized for 3D printing and print bed size

Alignment with “off the shelf part” availability for the perspex container

Proof of Concept (PoC) Build

Prototype build commenced

Revisions made to CAD model based off first build performance. Encountered issues were:

Base slots and side slots were too large, resulting in rice disappearing through the outlet

Concentricity misalignment caused uneven rotation and part interference

No constraint on the vertical movement of the tray and central axis

Final design confirmed

Slot size reduced

3D printed concentricity jigs developed to ensure proper alignment of rotational parts

Bushing developed to account for axial and concentric misalignment. A part which can easily be replaced with minimal effort.

Further Development

Support for this project is ongoing. The next phase of development will centre around taking the proven mechanical method, and improving the design around this core feature. This will include:

Universal inlet and outlet port adapters for fitment to household taps and drains

Increased size for greater rice capacity

Wall mounting and bracketry

Monitoring of the cleaning effectiveness through outlet water colour recognition