Flexible Curtain Track - Motorized

Vale Industrial Design was approached with the task of exploring a solution to bring an electric curtain track (with the ability to be hand-bent to shape around bay windows) into a manufacturer’s current product portfolio of manual, rigid curtain tracks.

Customer Brief and Specification

Existing prototype must fit into an existing track profile. Developing a new aluminium extrusion die is out of scope for this proof of concept phase

Minimum bend radius = 150mm

No specialist tools required for installation.

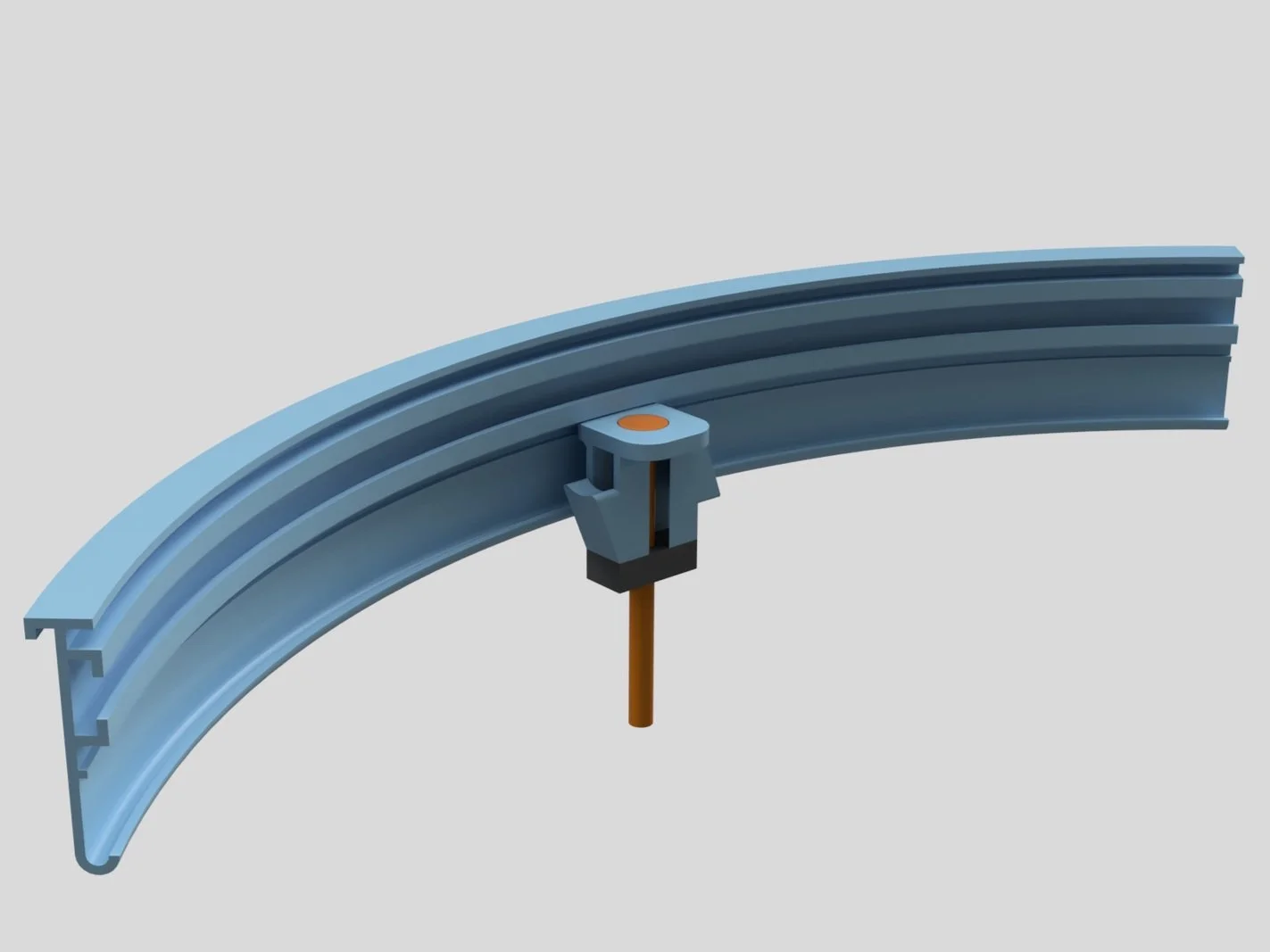

Concept Visualisation

This stage of the design process is very open, particularly for this project. The specification provided little constraint on the design direction and this encouraged a high level of divergent thinking. These drawings focussed primarily on developing the core drive system for the curtain carriers. Systems included:

Power screws (rigid and flexible)

Belt drive

Rack and pinion

Pneumatically operated with magnetic couplings

Linear motors

Concept Selection and 3D Modelling

After conversations with the customer and further considerations on the benefits and drawbacks of certain ideas, it was decided that 4 drive systems would be modelled and used as the foundation for separate Proof of Concept (PoC) models. Those modelled, were:

Capstan drive

Power screw

Simple belt and pulley

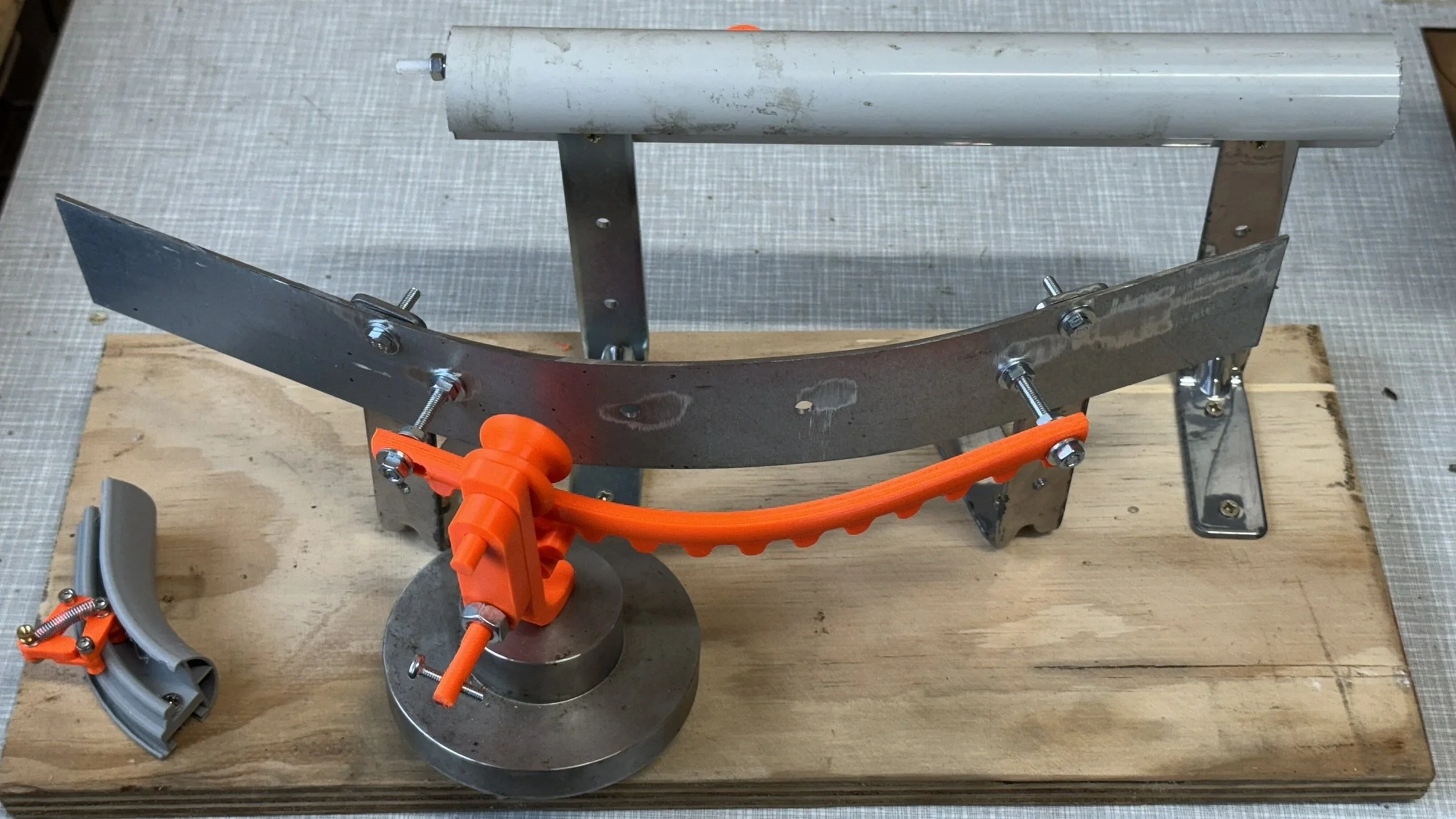

Flexible rack and pinion

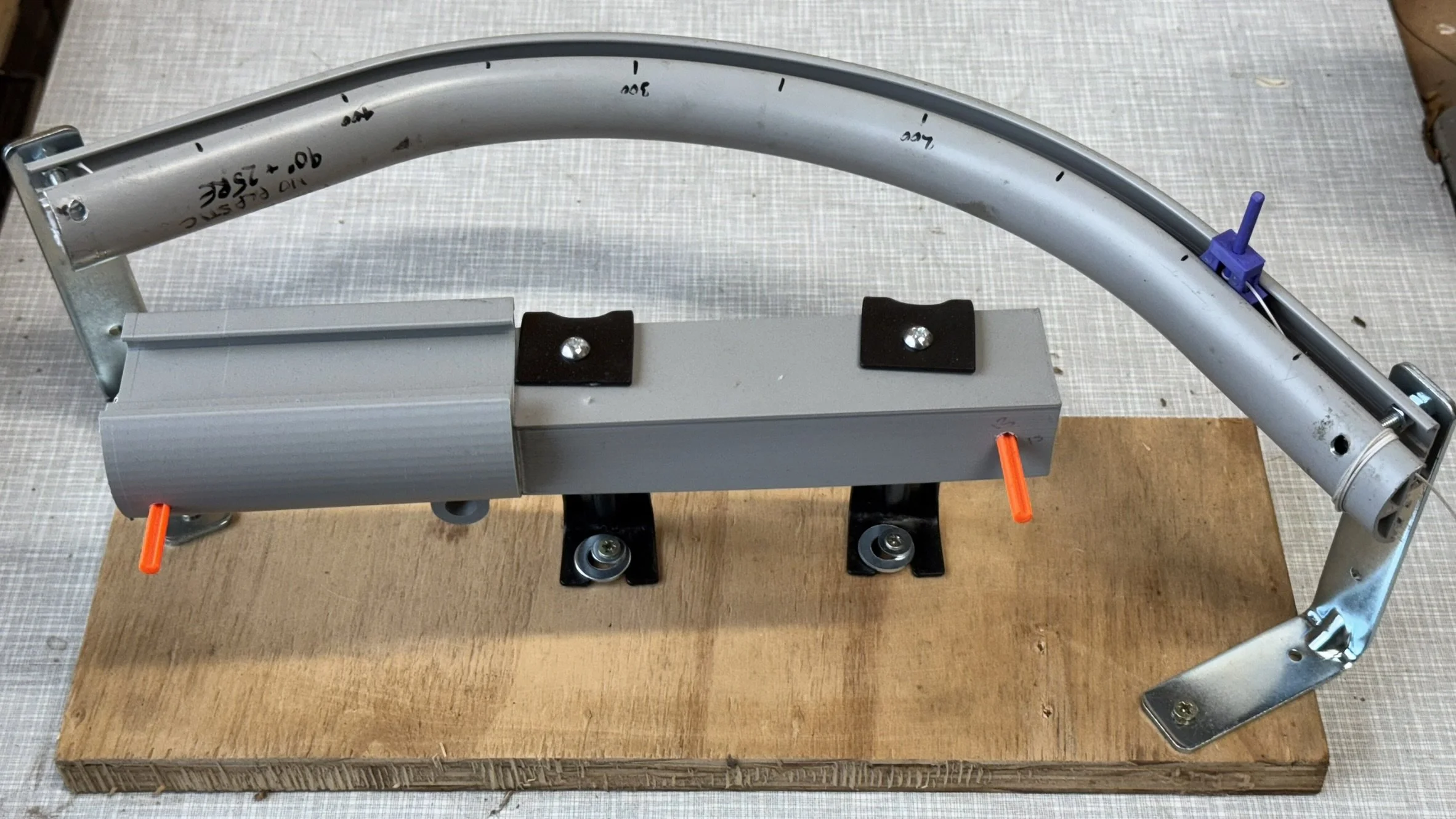

Proof of Concept (PoC) Builds

Drive systems were quickly verified by producing a number of quick “proof of concept” models. The aim here is to quickly develop cheap models that provide essential information to the designer and the customer as to the validity of certain tehnological methods.

Hand tools

General fittings like wood screws

Scrap track pieces from the manufacturer used

Basic 3D printed custom parts

Scrap plywood used for base

PoC Selection For First Build

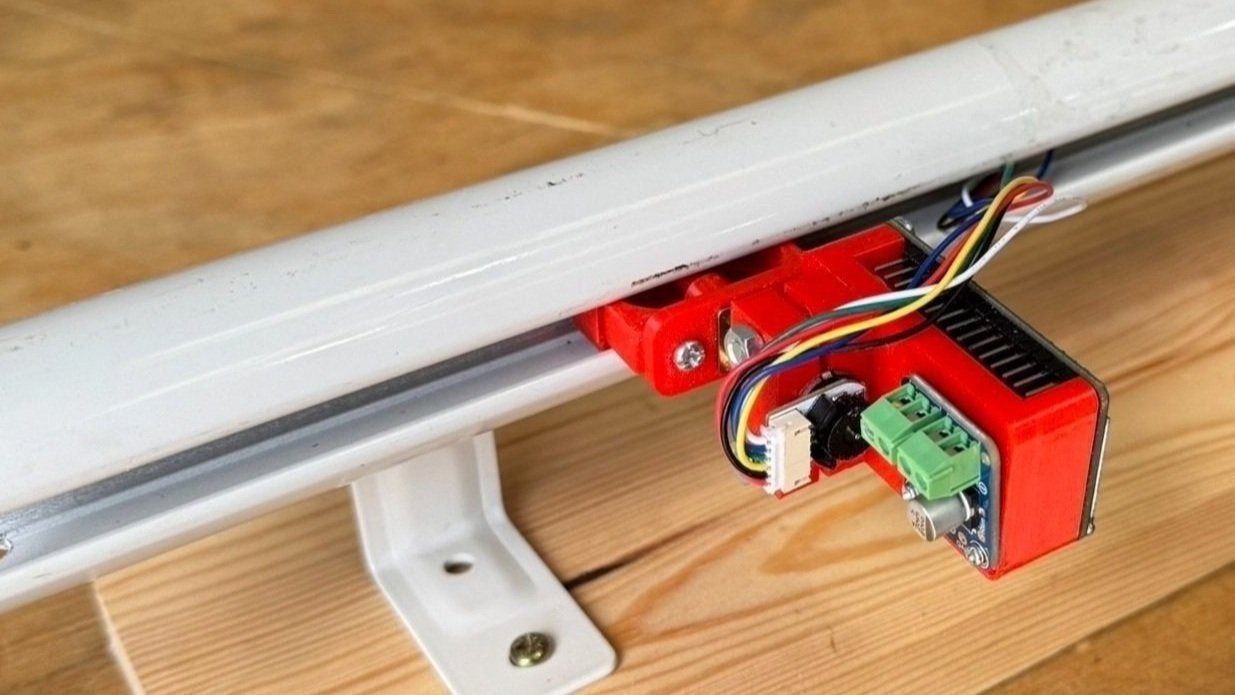

The capstan drive was identified as the most suitable drive unit to develop further. The design was progressed through provisioning for the electronic equipment required for wireless control.

New CAD based on the PoC design. Improvements made to enlarge the housing size to suit fabrication methods

Functional wiring diagram developed

Inclusion of ESP32 microcontroller, DRV8833 motor driver and Pololu micromotor

Webpage hosted interface for control over hardware WiFi

PWM for motor speed control

Services Used

Further Development

The customer will communicate when they want to push further with the development of this project. As of summer 2025, a great position has been reached. The effectiveness of the capstan drive unit has been demonstrated and whilst other projects now take priority, the next steps can be continued immediately. These are detailed below

Testing the drive unit on a curved track.

Power cable management

Suitable (larger) motor selection based on loading

Refinement of the drive for low friction with the track

Development of new aluminium track extrusion